Bed Sheet

Bed sheets come in two main varieties: flat and fitted. A flat sheet is simply a rectangular sheet of cloth, while a fitted sheet has its four corners, and sometimes two or four sides, fitted with elastic, to be used only as a bottom sheet. The fitted sheet may also be secured using a drawstring instead of elastic. The purpose of a fitted bottom sheet is to keep it from slipping off the mattress while the bed is in use. A particular way of folding and tucking while making the bed, known as “hospital corners,” is sometimes used when the bottom sheet is flat rather than fitted.

Materials

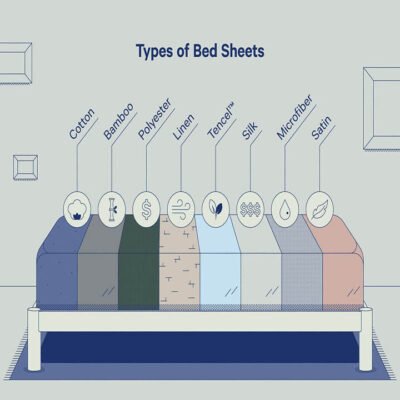

Cotton and cotton blends dominate the market, the most common blend being cotton/polyester. Cotton provides absorbency and a soft hand, while polyester adds durability and wrinkle resistance. Other common fibers used in the manufacturing of bed sheets include linen, silk, Modal and bamboo rayon, lyocell, Microtex or Microfiber, and polypropylene.

Construction

The quality of bed sheets is often conveyed by the thread count—the number of threads per square inch of material. In general, the higher the thread count, the softer the sheet, but the weave and type of thread may affect the “hand” of the material so that a sheet with a lower thread count may actually be softer than one with a higher count. Yarn quality also plays a part in the look and feel of sheets, as finer yarns tend to create a finer sheet fabric.